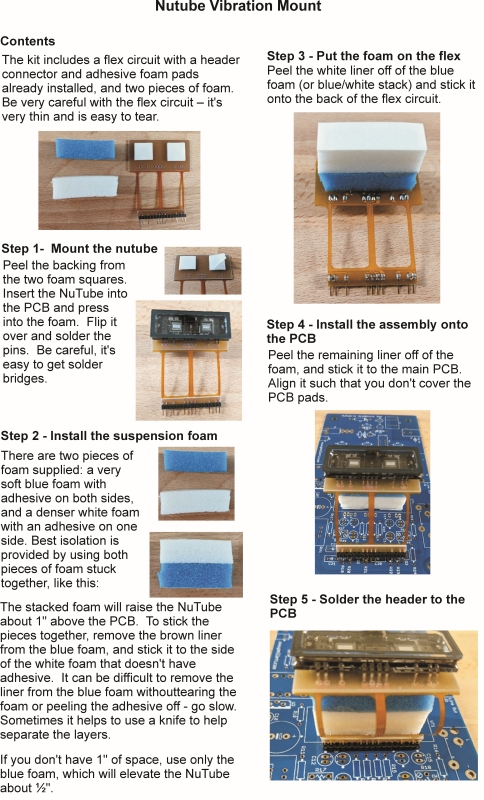

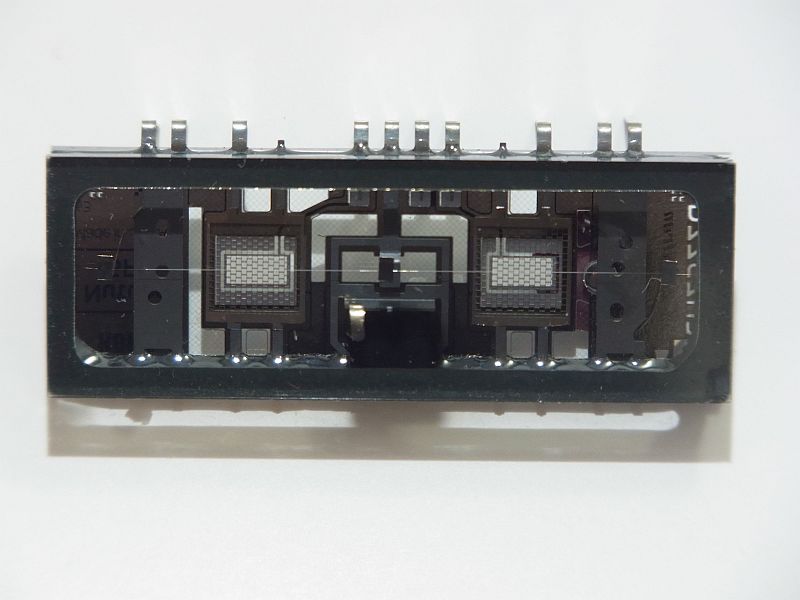

If you have use the Korg nutube (www.nutube.us) you probably know that it's really microphonic. The filament is a single wire under tension that acts like a tuning fork. You can see it in the photo below. (This is also true of the small "battery" tubes).

The problem can be pretty annoying, as it will transmit any shock to the PCB to the nutube, which makes a "ping" sound that can persist for some time. Although the operating point of the tube can improve things (higher current seems to make less noise), the only real solution that I have found is to mechanically isolate the tube.

I've tried a few different ways to do this. Korg also came up with their own vibration mount. But I really wanted a scheme that could be retrofitted into existing PC boards, both mine and others (like the Pass nutube B1). Here is what I developed:

I had some flex circuits manufactured that have two stiffener sections: on one, the nutube is soldered into place. On the other, a right angle header (missing some pins) is soldered. The header fits in the same holes on the main PCB that the nutube would fit into. The nutube is then suspended above the PCB on some very soft foam. When there is an impact applied to the main PCB, it isn't really passed to the nutube through the foam or the thin bits of kapton flex circuit.

I used this on the Sangaku DIY and it works well.

I will be selling these on my eBay store. The kit includes the flex with header already installed, foam pieces, and instructions (you can also download them).